That sensor data problem

A few weeks ago, I met with a number of IT consultants who had been hired to provide data science knowledge for an Industry 4.0 project at a large German industrial company. The day I saw them they looked frazzled and frustrated. At the beginning of our meeting they spoke about the source of their frustration: ‘Grabbing a bunch of sensor data’ from a turbine had turned out to be a pretty daunting task. It had looked so simple on the surface. But it wasn’t.

Data hungry Industry 4.0

In my last blog post, I looked at the Industry 4.0 movement. It’s an exciting and worthy cause but it requires a ton of data if executed well. Sensor data (aka industrial time-series data) from various assets and control systems is key. But acquiring this type of data, processing it in real-time, archiving and managing it for further analysis turns out to be extremely problematic if you use the wrong tools. So, what’s so difficult? Here are the common problems people encounter.

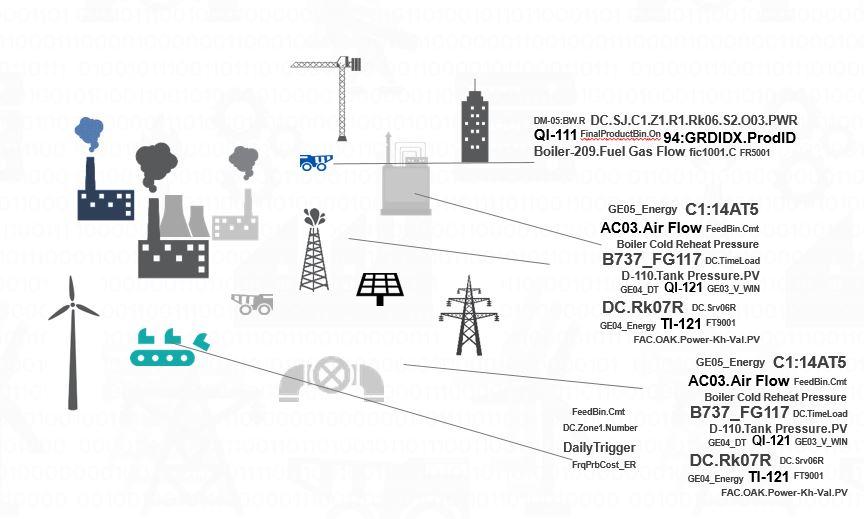

1. The asset jungle

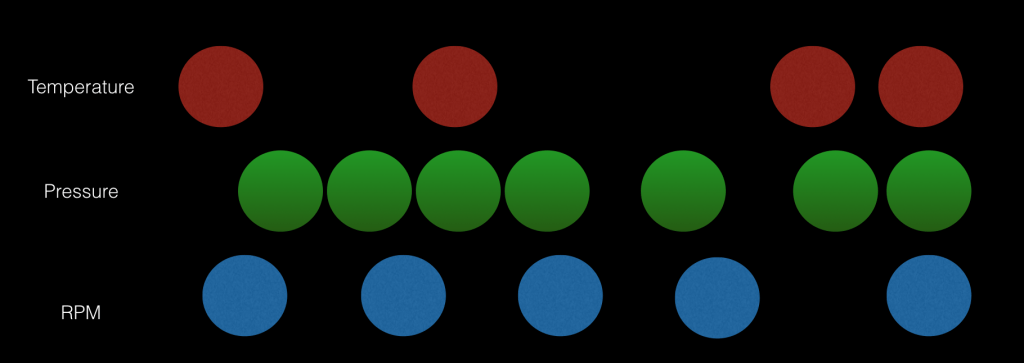

2. Speedy data

3. Big data volumes

- Storage: Think about the volume of data that is being generated in a day, week or month: 10k signals per second can easily grow to a significant amount of data. Storing this in a relational database can be very tricky and slow. You are looking at massive amounts of TB.

- Context: Sensors usually have a signal/ tag name that can be quite confusing. The local engineer might know the context, but what about the data scientist? How would she know that tag AC03.Air_Flow is related to turbine A in Italy and not pump B in Denmark?

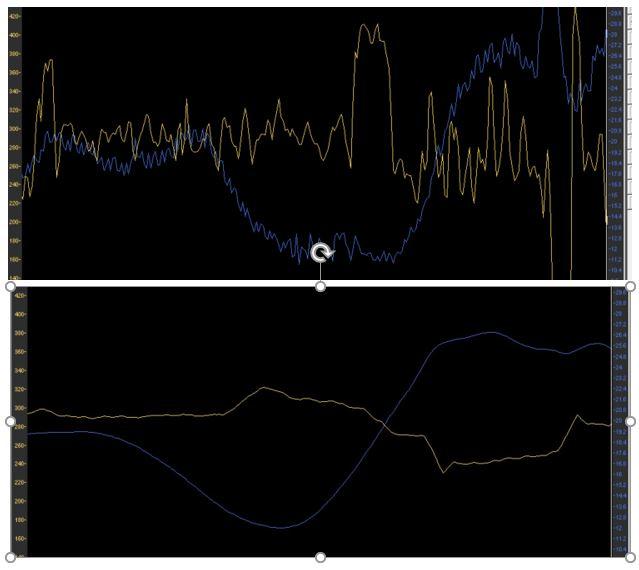

4. Tricky time-series

5. Analytics ready data