The OSIsoft PI System

In the last two blog posts, I spoke about Industry 4.0 and the challenges around working with industrial sensor data. Let me attempt to quickyl summarize the outlined problems: Industry 4.0 initiatives require a ton of time-series data. Acquiring, managing and analyzing this can be extremely challenging.

This is where the OSIsoft PI System comes into play. It’s been around for almost 35 years and has helped thousands of operations & IT professional manage their industrial sensor data. Today, I want to provide a high-level overview of PI for those people who are new to Industry 4.0 and the sensor data analytics space. (Please take a few minutes to read the prior blog post for a description of the basic business problems).

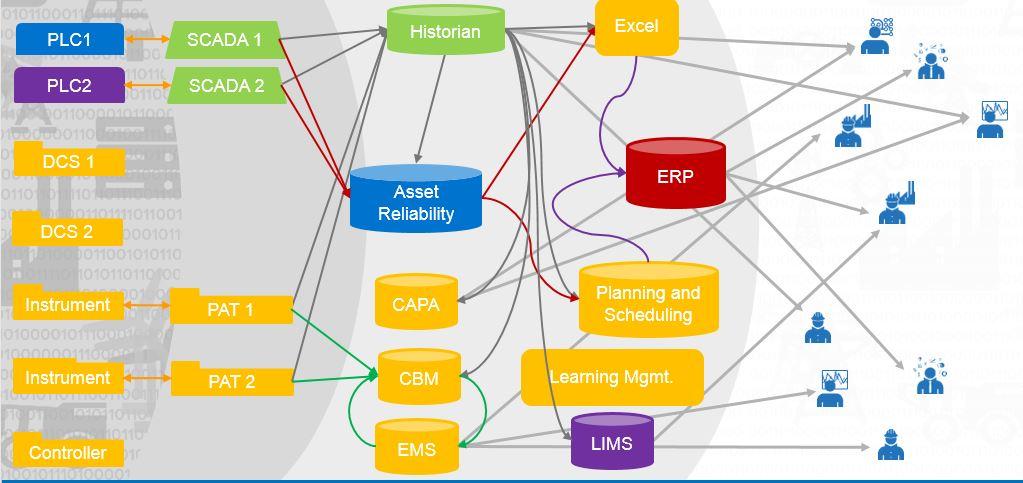

It’s a data jungle

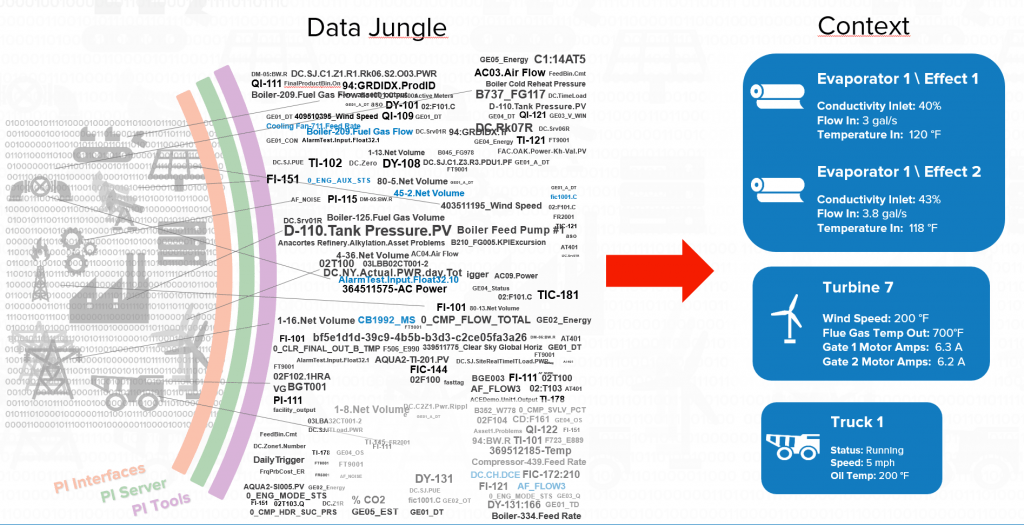

As discussed in the last blog entry, most organizations have massive struggles with capturing and managing data from their assets. If you happen to work in such an environment, you will know this scene:

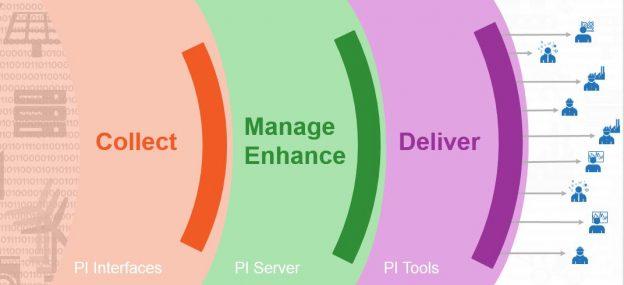

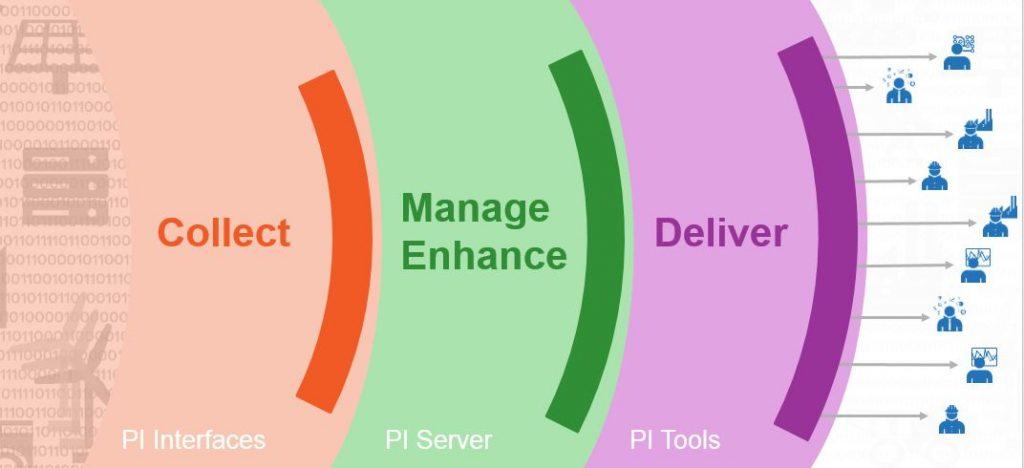

The OSIsoft PI System is all about simplifying this picture. It takes care of the full process for acquiring, archiving, managing and analyzing massive amounts of sensor data. Think of the PI System as a tool that takes care of getting data from the sensors to the users and applications that need it. This is basically a three step process:

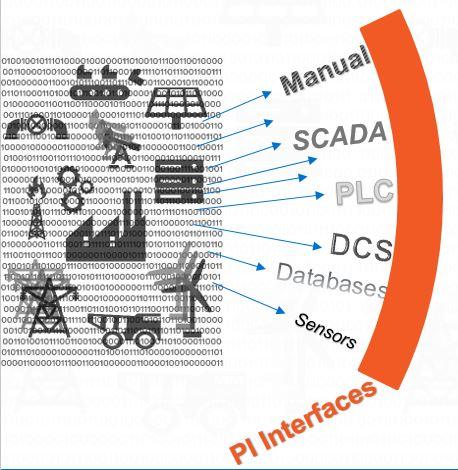

Data capture/ Collect

It starts with collecting data. As outlined before, this can be quite difficult. The PI System therefore offers a library of 450+ interfaces for virtually any kind of industrial communication standard or specific assets. There is no custom coding and no sherlock-holmesing of ancient APIs. This not only saves a tremendous amount of time but also significantly lowers risk (bad data, etc.). Further, the interfaces are smart: there is essential stuff like data buffering, filtering of bad data, etc.. along with auto-discovery of data sources. This ensures clean and reliable data.

Arrival in the OSIsoft PI System

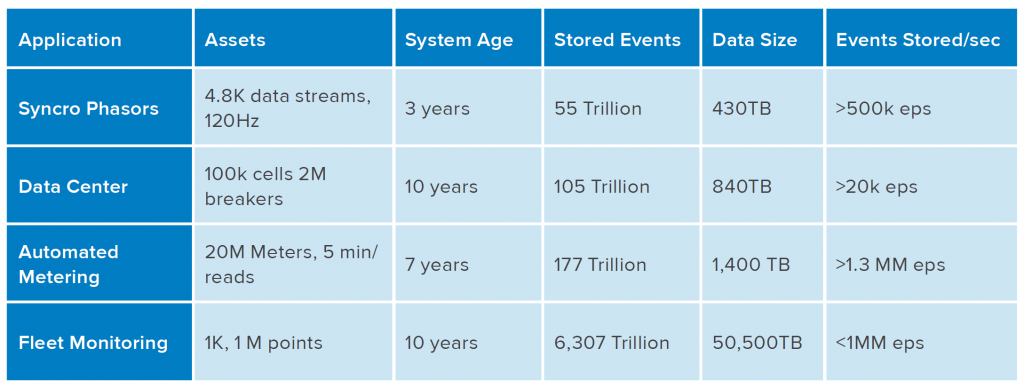

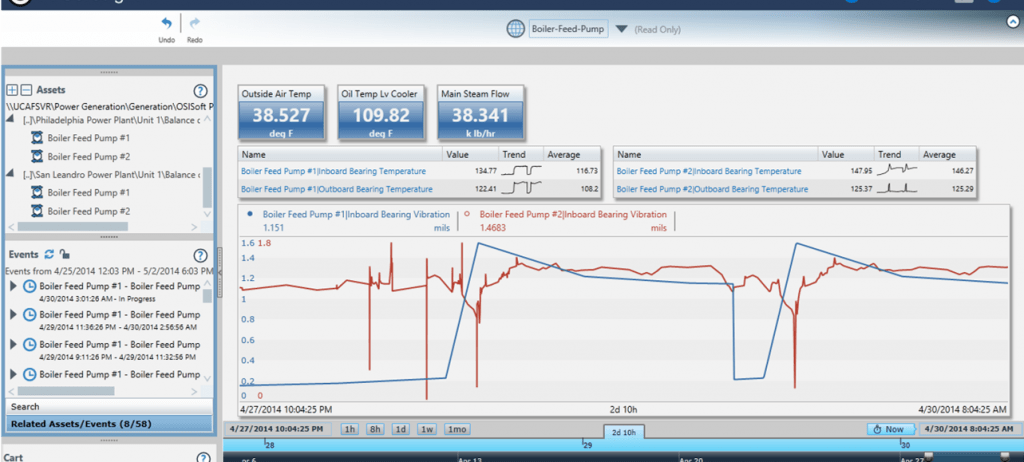

Once the data has been collected, it needs to be stored & prepared for analysis. This is a big job that most databases are not made for. Keep in mind: Industrial sensor data is fast. 1-100hz data are not unusual and asset operators require timely information (i.e. NOW). The PI System stores the data immediately upon arrival and provides it to the users or applications in real-time. Yes, it’s a real-time system and that’s why you see PI in so many control centers around the globe. But just providing data in real-time would not be enough to satisfy the requirements of Industry 4.0. The PI System therefore does some really cool stuff such as calculations (simple KPIs and very complex mathematical formulas), unit of measure conversions, tagging of events, sending notifications etc…..

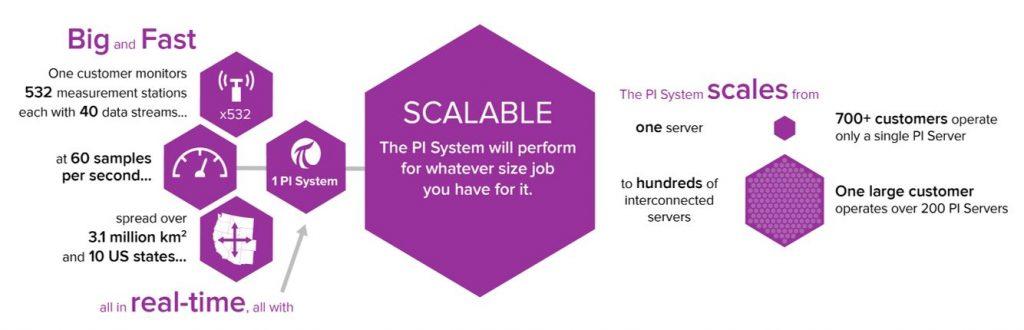

In case you want to perform historical analysis, you can also query data from 10-20 years ago in mere seconds. All data is hot and available – no more complicated archiving and waiting. This is cool stuff – think about the massive data volumes that we are dealing with here. The OSIsoft PI System does all this without any complaints – it is optimized to provide industry strength performance and reliability.

Context

How do you want to make sense of this much data? Keep in mind that sensor stream naming conventions are weird and funky (e.g. TI37.109-CP-TK9PV). A white paper by OSIsoft sums up this problem:

Typically, only a few initial users responsible for control system naming convention can fully benefit from the value built into the semantic namespace. Others spend valuable time trying to find and integrate the “right” operational data for analysis, roll ups. As a result, operational data often remain “dark” –untouched, underutilized or forgotten.

What if we could attach those weird technical names to a metadata model (like a hierarchy)? That’s exactly what the PI System does: Tag names are attached to real-world assets such as transformers, pumps & reactors. You can then navigate the tremendous amount of data through a business view and you can also create asset templates for easy system configuration. Each template can not only contain standards such as calculations, units of measure & other useful stuff (read this case study for a nice example). In effect, working with the data has suddenly become a whole lot easier. Comparing one pump with another is possible just like standardizing the sensor data models across equal assets. This is very powerful stuff in a world that drowns in data but is starving for information.

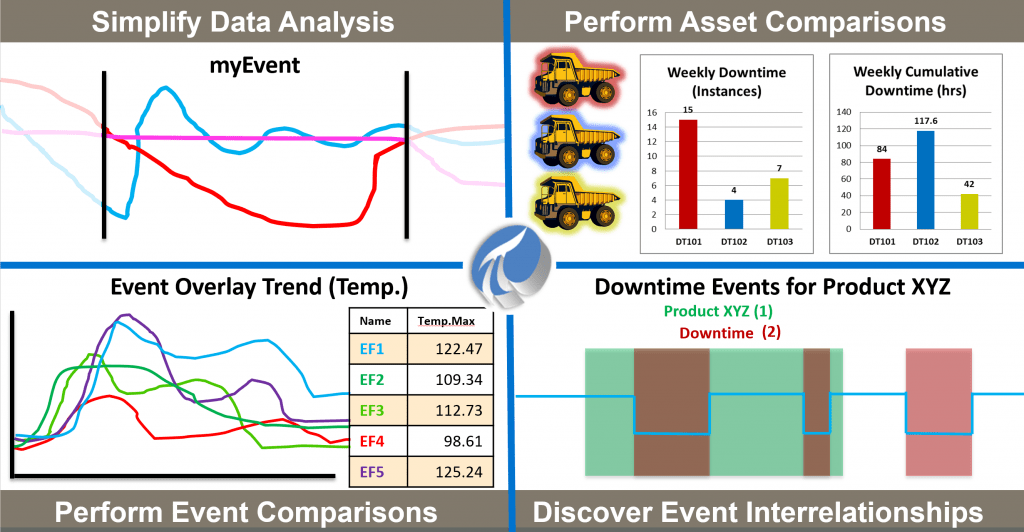

Name those events

Making sense of big data requires automated structuring of it. This is especially true for sensor data. In an industrial environment, we are always interested in analyzing specific events such as batch durations, start-ups, downtimes, etc.. These periods of time contain stories and insights that help you to improve processes. But they are notoriously difficult to find and compare when left unstructured. The OSIsoft PI System automatically bookmarking these events. You can then easily compare various batches or simply analyze what led to a downtime. This is really powerful stuff.

The last mile

Now we have captured, archived and prepard that sensor data. But data is only useful if you really use it. That requires the timely and effective delivery to users and business applications. Rest assured that the OSIsoft PI System knows how to do that as well. It starts with real-time visualization clients, it includes a powerful SDK and also a really neat BIG Data integration tool. Discussing this in detail would be too much for this post, however.

Big Data & Industry 4.0

To summarize this longer than usual post: The OSIsoft PI System is your best friend when it comes to managing sensor data. Relational databases are not made for this type of data.

Without an appropriate data infrastructure, Industry 4.0/ Digitalization efforts can quickly come to a grinding and frustrating halt. Does it require a lot get this up and running? No. Installations are usually fairly quick (we are taking days not weeks) and the hardware requirements are also nothing to worry about (it runs on my laptop).

As always, thanks for reading and sharing!